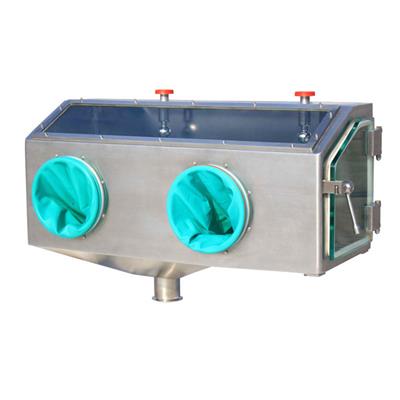

2. Use gloves for operation. Gloves can be thickened to resist damage or thin and high-feeling

3. Select H14 high-efficiency filter and pass PAO scanning leak detection test

4. Hydrogen peroxide can achieve 10⁶-log spore killing effect on the air in the isolator and the exposed surface

5. The safe entry and exit of items can be achieved through a variety of methods, such as airlock chambers, transfer cabins with RTP systems, etc.

6. A built-in power supply can be installed in the isolator, and a compressed air connector with a valve and a cleaning water connector can also be installed for water and air intake

7. The system is equipped with a Siemens logic controller (PLC) for fully automatic control of pressure and air supply volume, and has a pressure loss alarm function

8.10-inch touch screen control/12.1-inch industrial panel PC NetSCAD system, in line with the 2010 GMP computer system verification requirements

Maximum power:≤3000W

Touch screen:12.1 inch industrial control screen

Data trackingz:support

Power supply:220V±22V,50±1Hz

The minimum resolution on humidity:0.1%

Electronic signature:support

Airflflow model in isolator cabin:Vertical unidirectional flflow

The minimum resolution on temperature:0.1℃

Online leak detection:support

Adjustment range of the pressure inside cabin:-80~+80Pa

Wind speed:0.36~0.54m/s

Online glove leak detection:support

Operating size:1790×1050×740mm

Airlock room size:600×580×740mm

Dimensions:3130×1250×2385mm

Gas source:Filtered clean compressed air or nitrogen, air source pressure 0.4 ~0.6MPa

Cabin leakage rate:The pressure holding test is carried out when the positive pressure is 80 Pa, and the overall leakage rate of the isolator cabin is less than 0.5% vol/hour